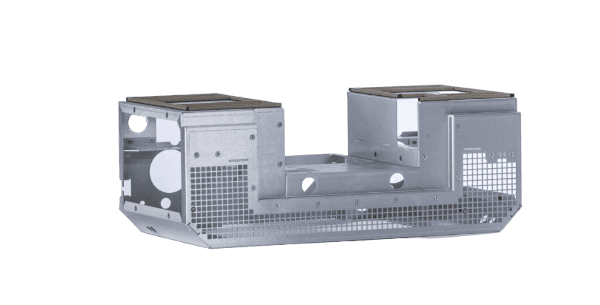

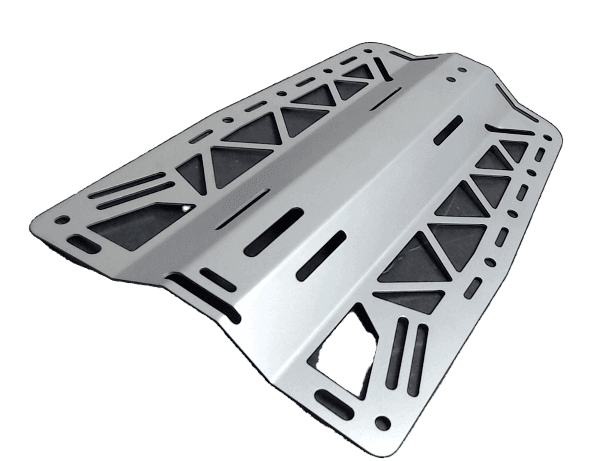

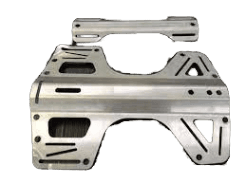

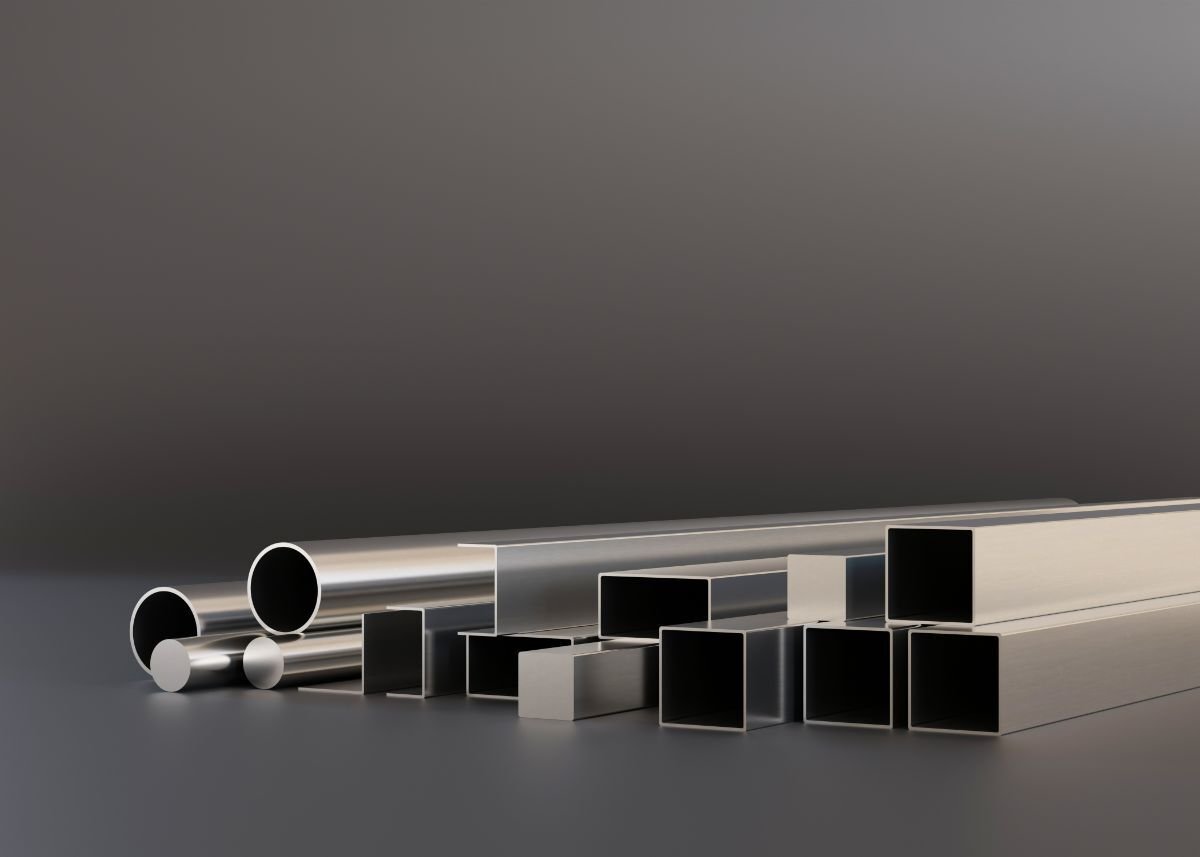

Metal Laser Cutting and Fabrication capabilities

Laser Cutting

This manifacturing process uses high power larser beam to cut a meterial sheet.

Allowable sheet thickness: 1-6mm (depending on material)

Allowable sheet thickness: 1-6mm (depending on material)

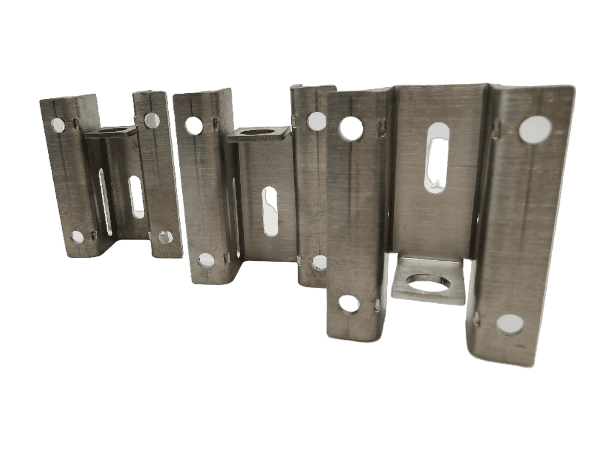

Bending

This manifacturing process uses die to produce a U-shape,V shape or chenal shape alogn a straight axis in ductil meterial.